The shipping industry is growing rapidly: every day, more and more parcels need to be shipped in the B2B and B2C sectors in shorter and shorter times. However, the increasing demands for fast delivery times and a diverse product range often lead to inefficiently packed boxes. These often contain only 15% product and 85% air or cushioning material – a burden on the environment and profitability.

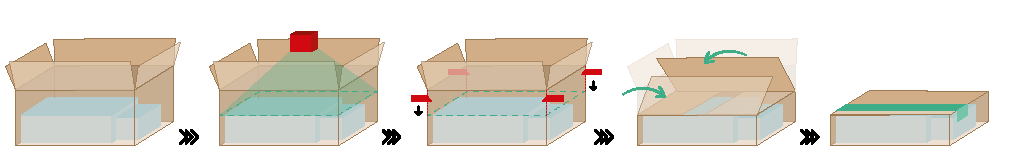

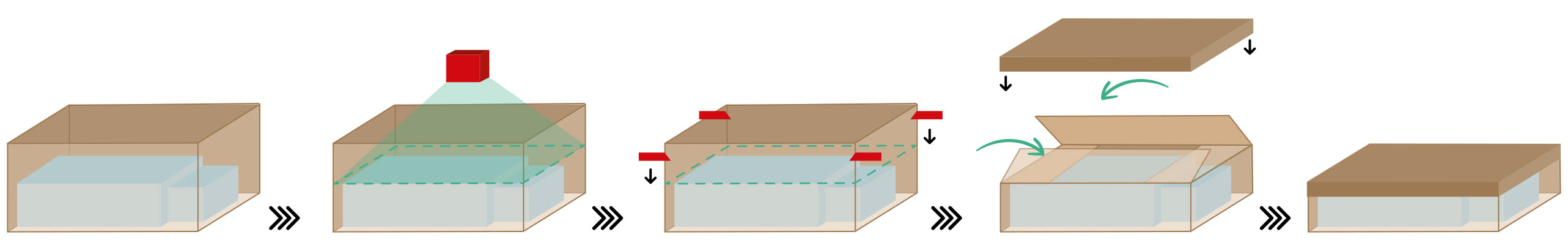

Our patented AMI case volume reducer makes your packaging process future-proof. The system automatically adjusts product-filled cases to their minimum required size and seals them securely for transport.