Individual automation solutions for every requirement

Every company has its own unique processes and the packaging process is designed individually by each company.

OPITZ is specialized in the realization of individual customer requirements: each of our machines is perfectly designed, laid out and tailored to your needs.

The manufacture of special machines is also one of our strengths. In joint consultation, we take your wishes and goals and develop a plant specifically for your packaging task.

Box opener

Goods arrive at the user's premises in packages that have to be opened and unpacked. OPITZ developed a system that precisely cuts open packages of various sizes using oscillating knives without damaging the goods.

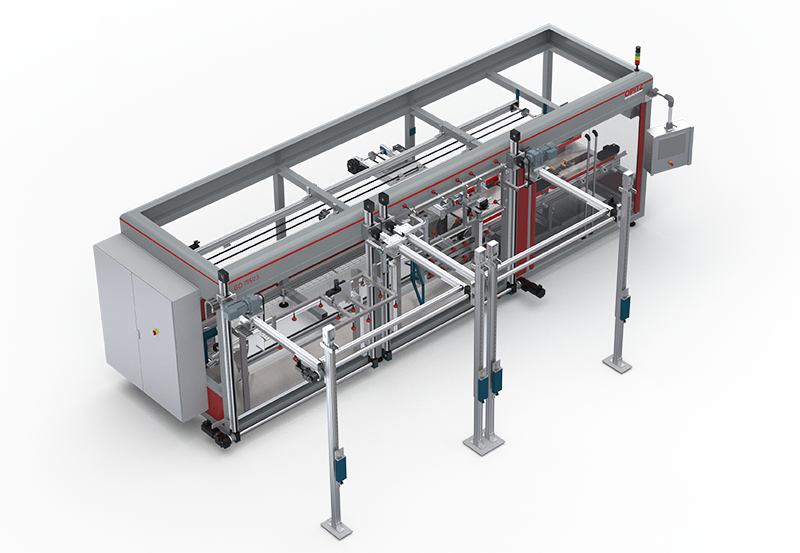

Box erector for oversized formats

(with integrated depalletizing)

The customer's goal was to erect extremely large carton formats fully automatically. To optimize manpower requirements, the carton blanks are lifted directly from the pallet. Click here to see how the system works.

Innovative spirit as a competitive advantage

The packaging industry is undergoing strong growth and rapid change.

In this environment, our innovative spirit is our most important tool to maintain and further expand our lead over our competitors in the future.

Case Studies:

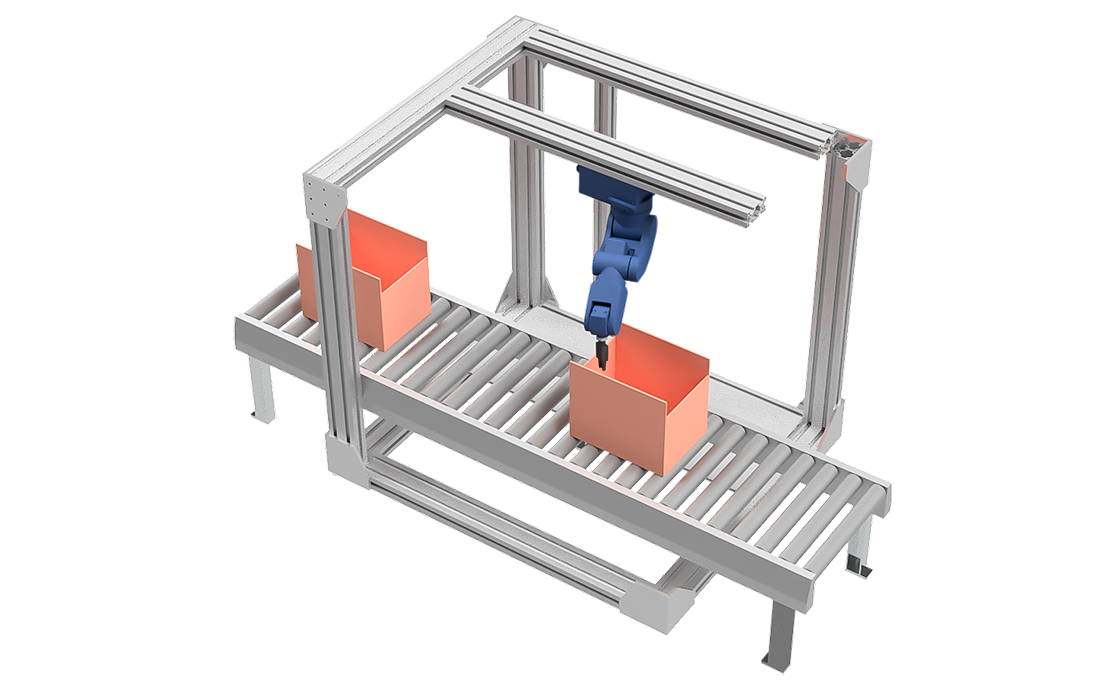

Automatic grooving of cartons

Cartons that are to be reduced in height must have pre-stamped so-called grooves on which the carton flute breaks during folding in order to be able to fold an accurate lid. Until now, this had to happen during the production of the cardboard. Thanks to our own development, we can now emboss this creaser groove individually in each carton, depending on the height of the packaged goods. A robot-guided tool stamps the groove directly above the packaged goods.

Automatic insertion of protective / cushioning material

One major challenge of the growing mail order business: very high consumption of packaging, filling and cushioning material. The shipped goods should be protected in the best possible way. However, this can result in high costs for the sender and also pollutes the environment. The aim is to rationalize the process of inserting filling material. Based on a highly complex algorithm, we automatically place the minimum necessary amount of padding material exactly where it is needed. This reduces consumption to a minimum. The result is an innovation that is unique in the world.